Hello from the farm! It has been one wet week around here, and I’m sure it’s been the same for a lot of you as well! Fortunately, we have very sandy soil, so water drains pretty quickly. It’s handy when we have an abundance of water that needs to get moving, but as we talked about in some previous newsletters, it can pose a problem later in the season when we inevitably run into dry spells.

There’s quite a bit of activity on the go this week, and I thought I’d fill you in on some of it!

We were busy baking and sorting preserves earlier this week, and then dropped off all Spring/Easter orders yesterday, direct to the doorsteps of those who ordered. Thanks so much to everyone who supported our Farm Kitchen, and we hope you enjoy your pies, pretzels, and more!

Meanwhile, our seeding and field crews have also had lots on the go. Keep scrolling for a sneak peek at what they’ve been up to!

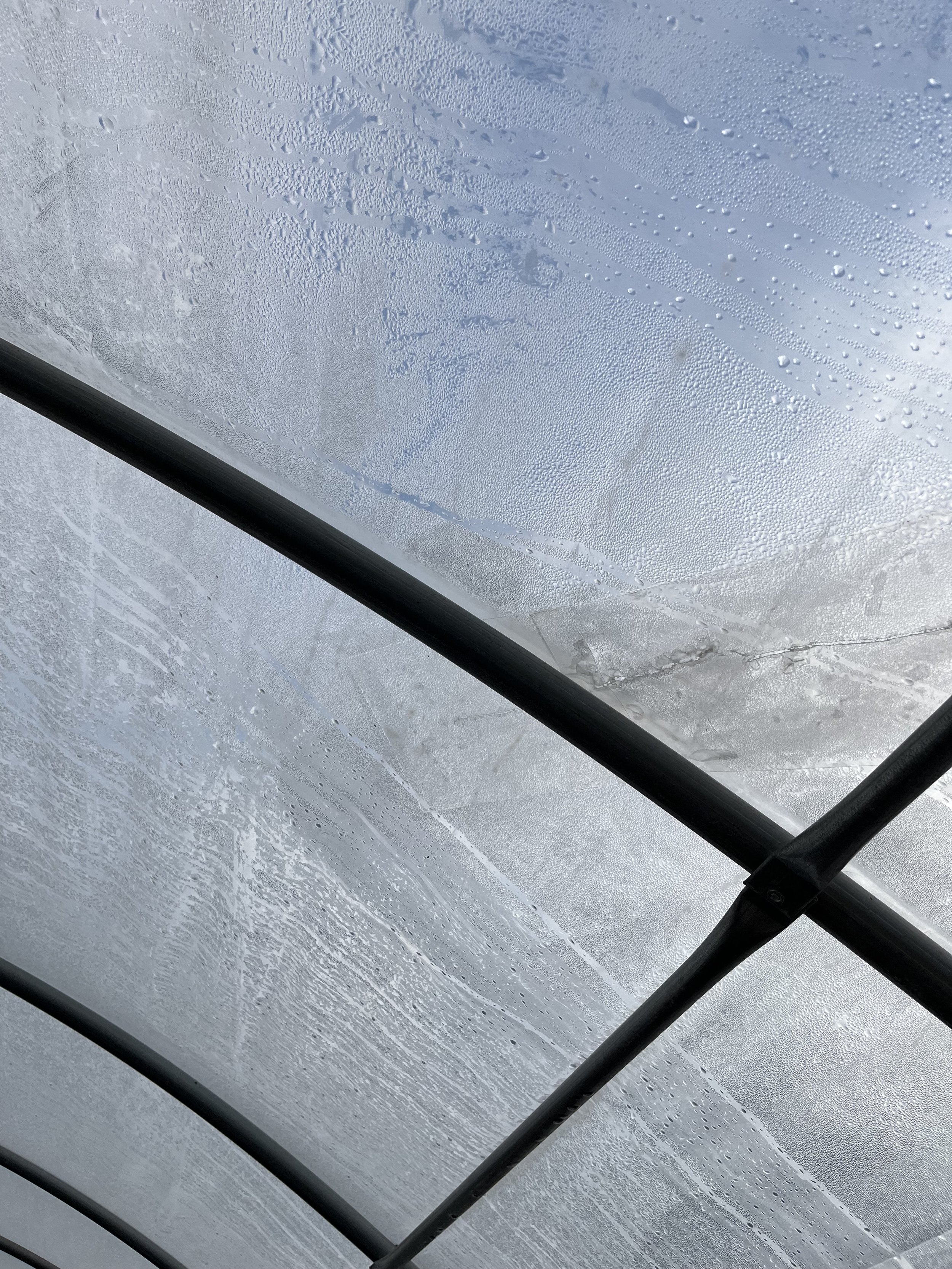

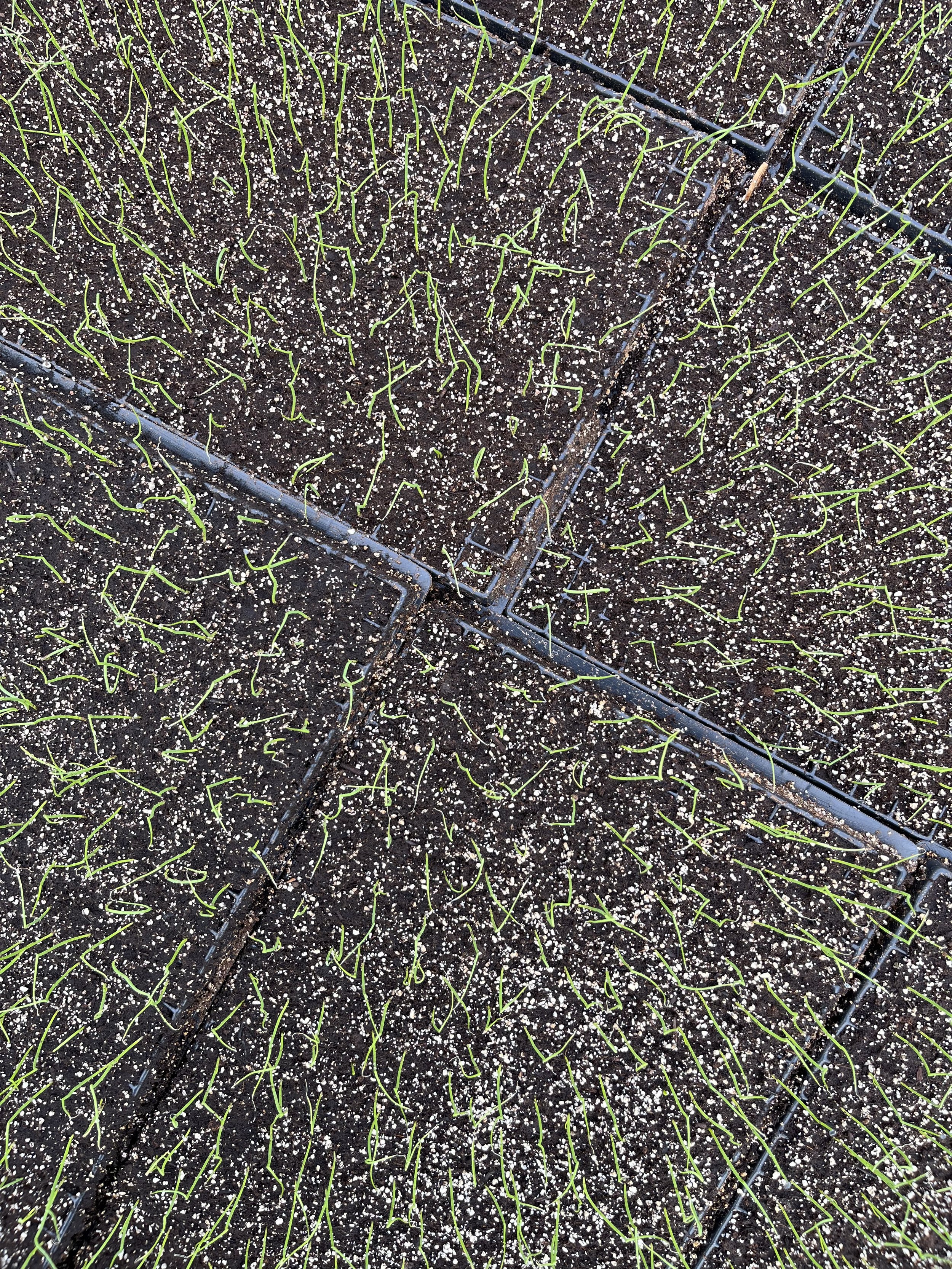

First up, as requested by our youngest reader (a 6-year-old from Toronto!) here are some photos of our germination trailer. Several of our crops hang out in here after being seeded into trays, and before heading out into the greenhouse. The germination trailer is heated to 85°F and has a humidity of 90%. The humidity is actually just thanks to the moisture found in the trays themselves, which are wetted down after being seeded. The trays stay in the germination trailer for anywhere from 24 – 72 hours: muskmelon for 24 hours, watermelon for 48 hours, and tomatoes for 72 hours. This time in the germination trailer allows for the emergence of 1/8 of an inch of the radical root (primary root) and sets the plant up for success throughout the season.

Next, two of our earliest crops (rhubarb and asparagus) are in their beginning stages of the season. Our asparagus fields are being mowed: the previous season’s plants grow up and go to fern after we finish harvesting, and we leave them out in the field over the fall and winter to act as a natural windbreak. Meanwhile, the rhubarb is starting to push its way up out of the soil for another year.

The first of our two cold frame greenhouses is officially full! We’ve got red, green, and Boston lettuce in there, along with spinach, Swiss chard, and potted chives and basil.

Our beekeeper Nathan was out checking on the beehives earlier this week, and we are thrilled to report that they are looking great! Check out this packed hive!

Finally, (not pictured) our blueberry bushes are being pruned this week! It may seem counterintuitive to cut off parts of a plant, but cutting back the older canes on the bush encourages more productive growth of new canes for future seasons. We will repeat the same process with our raspberry crop!