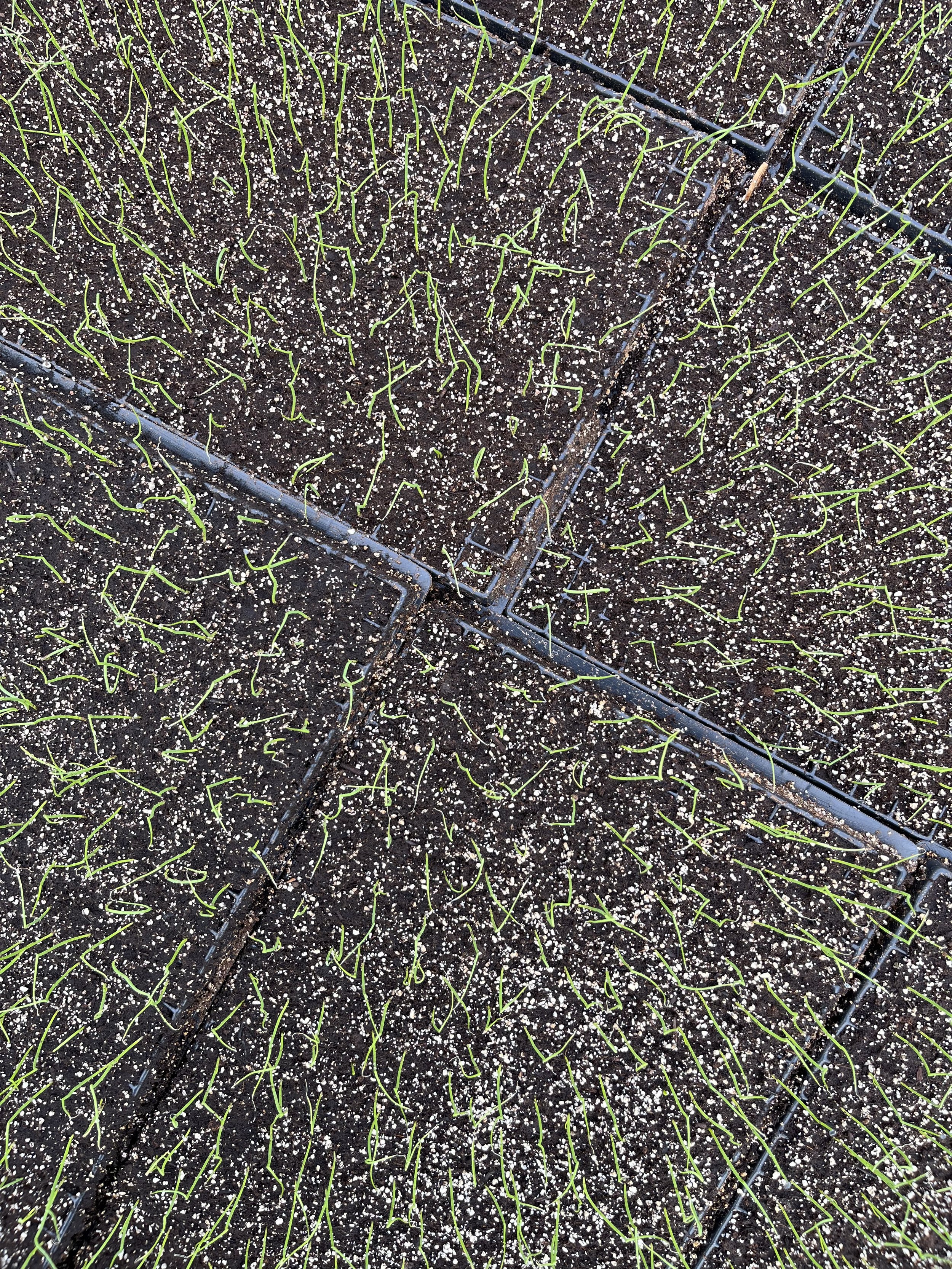

May on the farm means everything is moving at full swing. It’s a tricky month, due to the cold temperatures we still feel most evenings, and means we are trying to balance transplanting and crop growth with frost protection. We've had some long nights worrying about and working hard to keep everything safe, but it's definitely worth it!

The best part of May is that home deliveries have started, Farmers’ Markets are opening, and our Farm Market (including the Farm Food Truck!) is up and running. After a long winter, it feels so wonderful to connect with all of you in person again!

ON THE FARM

✅Farm Events

Meet The Bees // May 31st + June 7th

Put on a suit and follow our beekeeper, Nathan, to the hives to learn all about beekeeping. Finish up with a sweet treat enjoyed on the farm.

Harvest Brunch // July 5th + 19th

Spend time in the fields and harvest your own fruits and vegetables. Learn about your produce and culinary tips from Registered Dietitian, Alex Chesney. Enjoy your local and delicious brunch on the farm.

✅Farm Market

Open Daily 9am - 5pm. Always stocked with pre-picked produce, preserves, baked goods, and Black Angus Beef. A convenient way to shop local.

✅Pick Your Own

Asparagus and rhubarb are both available in our Pick Your Own fields. Be a farmer for the day and experience harvesting your own produce. Plus, this is the most budget-friendly option we have available. Open Monday - Saturday 9am to 5pm.

✅Farm Food Truck

Now open 7 days a week 11am - 5pm! Serving Black Angus Smash Burgers, fresh-cut fries, milkshakes, and poutine. Everything on the menu is made from scratch using produce grown on the farm. Make a day of it and enjoy our walking trails, kids’ playset, or hanging out with our chickens and cows.

📍Farm Address: 775530 Blandford Rd, Innerkip

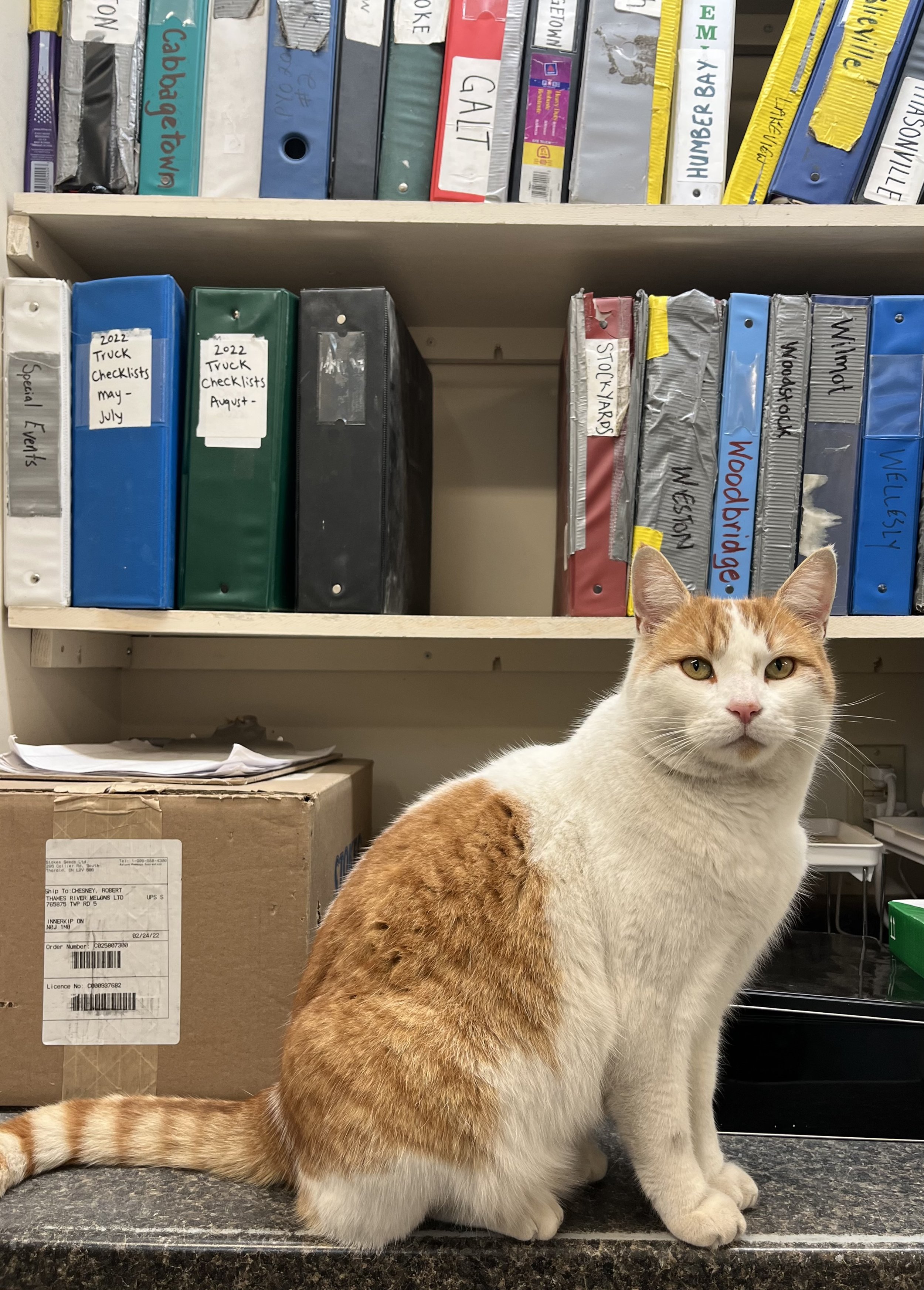

OFF THE FARM

Starting this weekend, you can find us at the following Farmers’ Markets and Pop-ups. Be sure to stop by and say hello! 👋

✅Farmers’ Markets

Click here for the full list of Farmers’ Markets we’ll be attending this season.

✅Daily Pop-ups

Cambridge ONRoute (both East and West)

Toys R Us in Kitchener (419 Fairway Rd S)

FROM THE FARM

🐝An update from our Beekeeper, Nathan:

The bees' springtime is for pollination and growth. They're hard at work in the apples, peaches, and strawberries. As they fill their hive with this food and new bees, they prepare to swarm. They make a new queen, who stays behind with half the bees while the old queen takes the other half to start a new hive. To avoid losing bees this way, we split the hives before they swarm, giving them more space to grow.

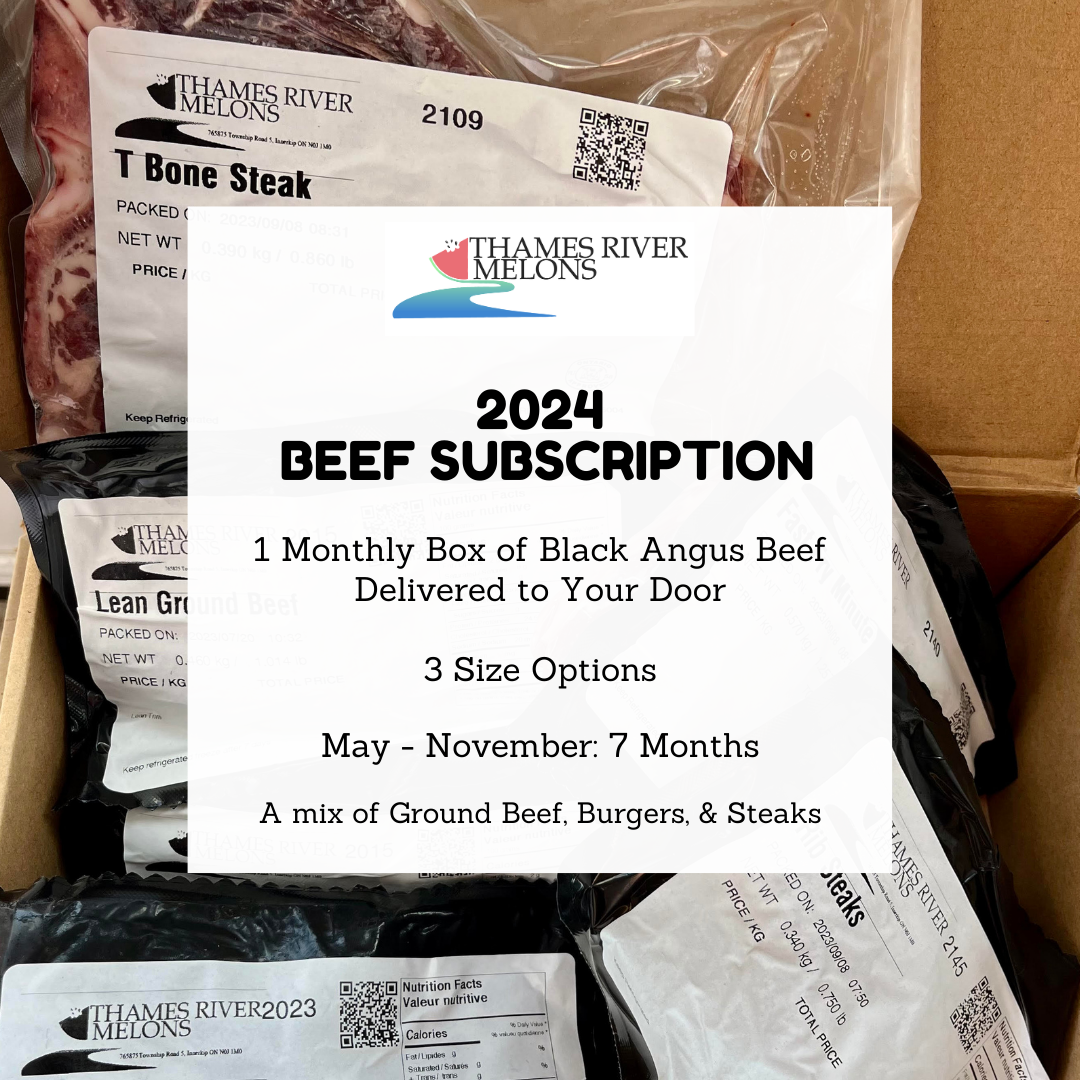

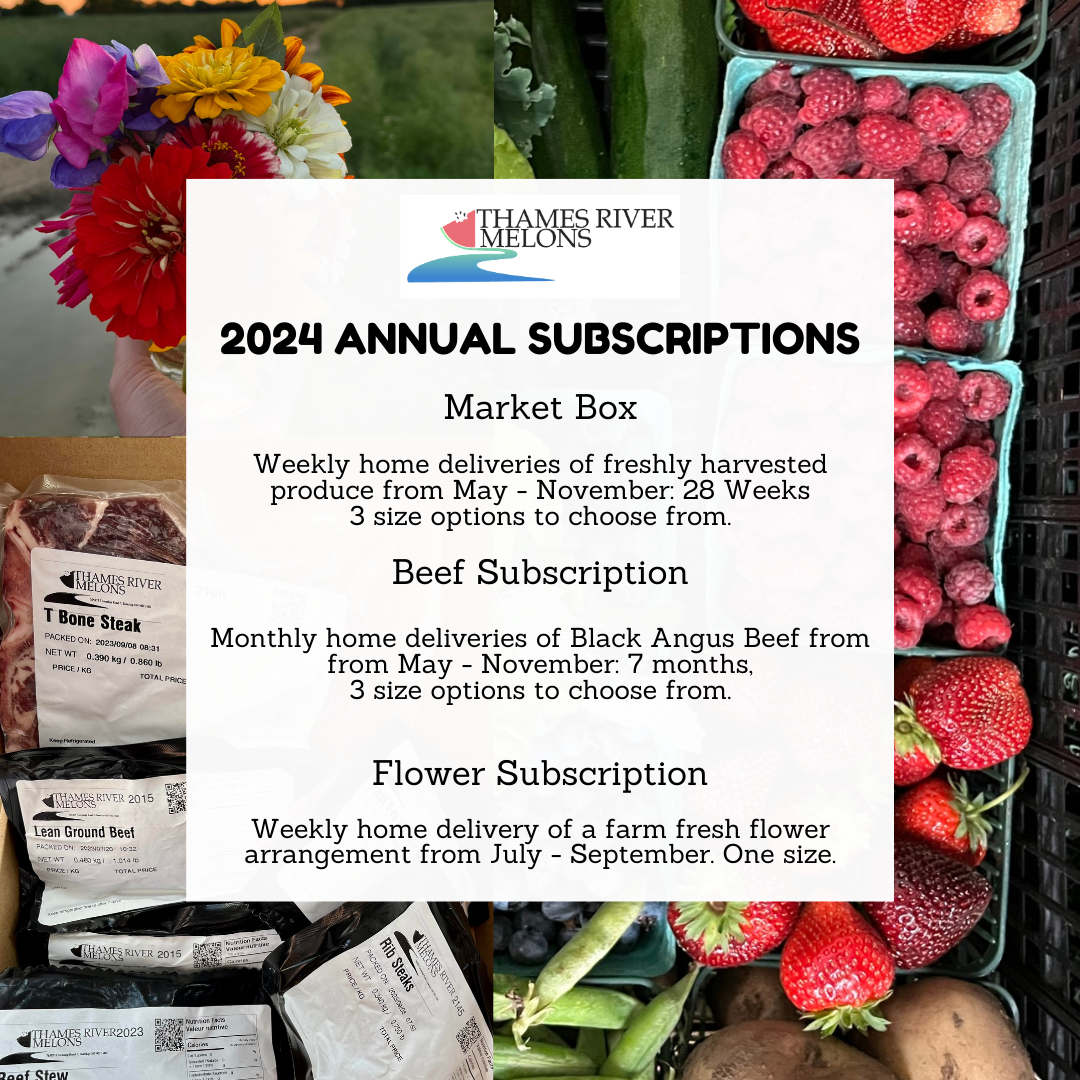

🐄Black Angus Beef Update:

Our website has been restocked with all of your favourites. We work directly with a local butcher to provide you with fresh and delicious cuts from our very own herd. We recommend stocking up your freezer with steaks for easy summer meals. Click here to order Black Angus Beef for delivery.

Farm Kitchen Update🥧

Our team is back baking daily in our Farm Kitchen! Fruit pies, muffins, savoury pies, focaccia and more are being whipped up daily, and are available for sale via home delivery or here on-farm. We also send a selection of pies to many of our Saturday farmers' markets. If you have a special event you need something delicious for, be sure to reach out and place an order!